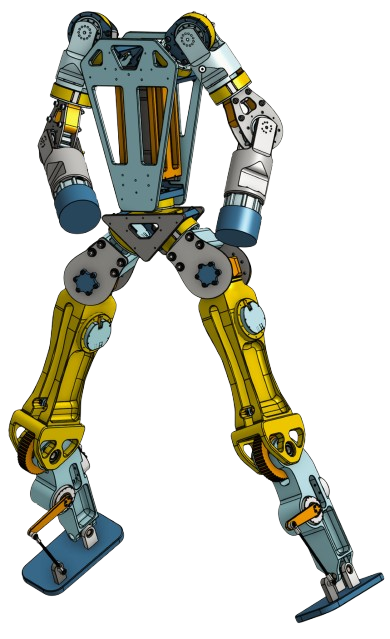

MOHRA

Machined Open Source Humanoid Robot

Senior Project 2024

Developing a full robot assembly from scratch, in conjunction with K-Scale Labs.

Prioritizing:

Gear Generation Repo

gearage

Initiated 2024

Leverage exposure & intuitions developed working an industrial gear-making internship to evolve publically available but hard-to-understand gear design mathematics and principles into more comprehensible & accessible code.

Not just drawing an involute curve on a circle:

Sprag Element Clutch Integration

BajaSAE, 2021-2023 Seasons

From SR21 competition vehicle, we found that the existing front wheel drive overrunning clutches were fully unsuitable for off-road, high-intensity service. Immediate need for a new option for upcoming years' deepening reliance on FWD performance.

Four Wheel Drive Torque Limiter

BajaSAE, 2021-2024 Seasons

New rules-required front wheel drive system found to have highly volatile and poorly understood load behavior through the front drivetrain system.

Defined a new project to implement a 'mechanical fuse' into the system to mitigate overloads, enable further lightweighting of outboard components (less unsprung mass, increased compliance for suspension design), and allow for empirical evaluation of typical load behavior in competition conditions.

3D Printed Titanium

Rear Load-Bearing Drive Shafts

BajaSAE, 2024 Season

Combining the driveline and suspension into one component, the rear drive shafts are a critical component for both performance and optimization. Utilizing the now-expanding technology of electron-beam melt (EBM) printing, the assembly was condensed to a single part while also removing stress concentrations at interfacing geometry and enabling non-uniform internal geometry for improved strength-to-weight.

Off-Grid Solar Power + Business, Malawi

Humanitarian Design Corps / EWB, 2020-2023